In today’s fast-evolving world of technology, materials, and industrial processes, the term UVLACK has started to gain prominence. While it might sound like a niche technical phrase, UVLACK carries substantial weight in various industries ranging from coatings and protective layers to cutting-edge applications in construction, manufacturing, and consumer products. To fully understand what UVLACK represents, it’s essential to dive deep into its meaning, its applications, and the transformative role it plays in modern sectors. This article provides an expert-level exploration of UVLACK, its importance, and the industries it continues to shape, offering a comprehensive insight for professionals and enthusiasts alike.

What is UVLACK?

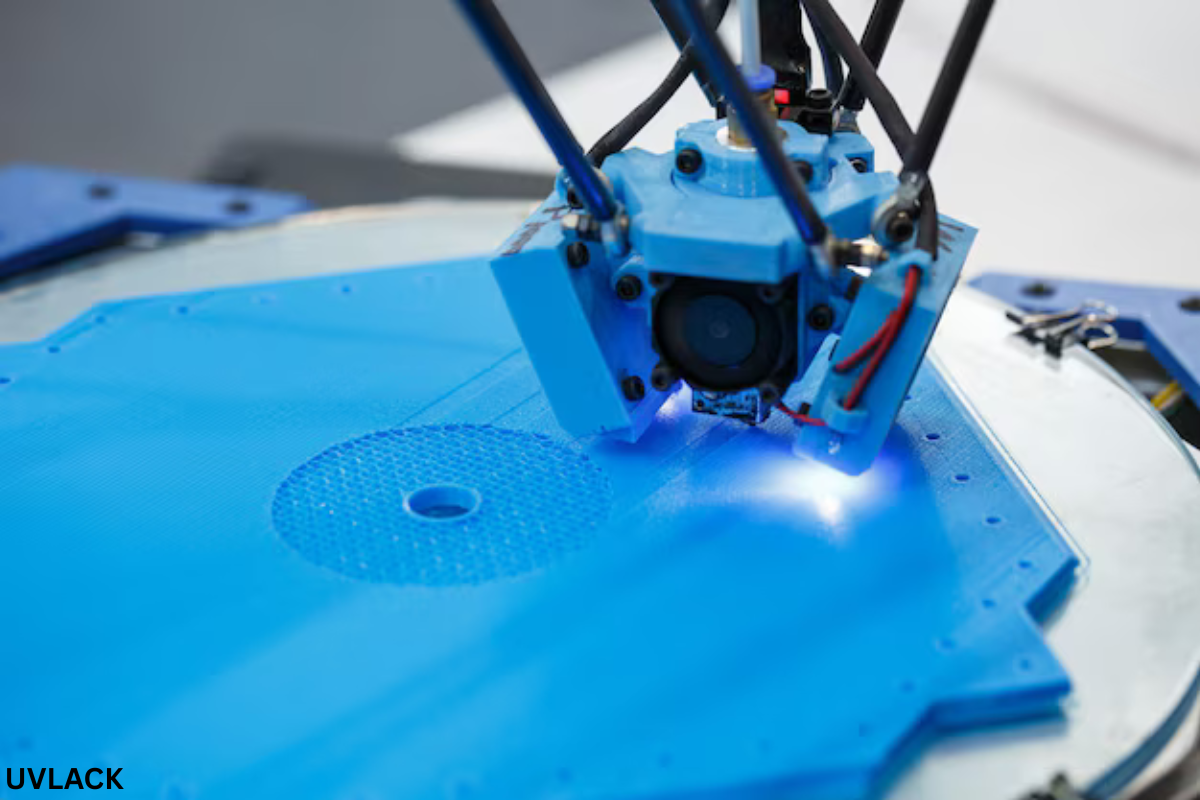

UVLACK is most commonly associated with advanced UV-curable coatings, finishes, or materials that provide surfaces with enhanced resistance, protection, and durability. The term combines the concepts of ultraviolet (UV) light and “lack,” derived from the German word for varnish or lacquer. This essentially highlights UVLACK as a special category of finishes that cure or harden when exposed to ultraviolet radiation. Unlike conventional finishes that may require extended drying times or chemical hardening, UVLACK is characterized by its efficiency, speed, and robust final properties, making it an indispensable tool in industries where time and quality are equally important.

The Science Behind UVLACK

At the core of UVLACK lies a process called photopolymerization. In this method, liquid polymers are exposed to UV light, which triggers chemical reactions that harden the surface almost instantly. Unlike traditional drying, which relies on solvent evaporation or heat, UVLACK leverages light energy to transform a liquid finish into a solid protective coating. This technology not only shortens production time but also provides a higher degree of resistance to wear, scratches, and environmental exposure. The efficiency of this reaction is one of the main reasons why UVLACK continues to gain momentum across various fields.

Key Properties of UVLACK

The standout features of UVLACK include high durability, superior surface protection, and quick curing. Once applied, UVLACK produces a finish that resists scratches, chemicals, and UV radiation from the sun, ensuring longevity for treated products. It is also known for its gloss retention, maintaining a polished and aesthetically appealing surface over extended periods. Furthermore, UVLACK coatings are environmentally friendly, as they emit fewer volatile organic compounds (VOCs) compared to traditional finishes. These properties position UVLACK as a sustainable and performance-driven choice in today’s environmentally conscious industries.

Applications of UVLACK in the Furniture Industry

One of the most prominent uses of UVLACK is in furniture manufacturing. Wood and composite surfaces treated with UVLACK display a flawless finish that resists scratches, stains, and sunlight damage. Furniture manufacturers prefer UVLACK because it allows mass production with consistent quality, as the rapid curing process significantly boosts production efficiency. Moreover, the finish maintains its brilliance for years, making UVLACK a favorite for high-end cabinetry, flooring, and decorative furniture pieces. Its blend of aesthetics and practicality ensures long-lasting customer satisfaction.

UVLACK in the Automotive Industry

The automotive sector increasingly relies on UVLACK coatings to deliver durable and visually striking finishes. Cars treated with UVLACK maintain a glossy, showroom-like appearance for extended periods, withstanding harsh sunlight, chemicals, and weather conditions. The high resistance to scratches and abrasions makes it ideal for protecting car exteriors and interiors alike. Automotive designers also appreciate UVLACK for its versatility, as it can be applied in varying gloss levels, from high-gloss reflective finishes to matte modern designs, allowing for creative and durable customization.

UVLACK and Electronics

Electronics manufacturing is another area where UVLACK proves vital. Devices such as smartphones, tablets, and laptops benefit from UVLACK coatings that not only enhance visual appeal but also protect against daily wear and tear. With the rise of touchscreens, durability has become a critical factor, and UVLACK offers the resistance needed for these high-contact surfaces. Its fingerprint resistance, combined with its protective qualities, makes it ideal for modern gadgets. The fact that UVLACK can be applied in thin yet highly effective layers ensures that devices retain their sleek design while gaining extra protection.

Environmental Advantages of UVLACK

In today’s world, sustainability is at the forefront of material selection. UVLACK stands out as an eco-friendly option due to its low emissions and energy efficiency. Since the curing process relies on UV light rather than heat or chemical evaporation, less energy is consumed, and harmful pollutants are minimized. Additionally, the durability of UVLACK extends the lifespan of products, reducing the need for replacements and contributing to long-term environmental benefits. These eco-conscious characteristics make UVLACK an attractive choice for industries committed to green practices.

Comparing UVLACK with Traditional Coatings

When compared to traditional coatings, UVLACK demonstrates clear advantages. Traditional coatings may require hours or even days to fully dry and cure, while UVLACK completes the process within minutes under UV exposure. This speed allows manufacturers to streamline production, reducing downtime and costs. Additionally, UVLACK provides a tougher, more durable surface compared to many conventional options. The enhanced chemical resistance and reduced environmental impact further highlight its superiority, making UVLACK the preferred solution in multiple sectors.

Technological Advancements Driving UVLACK Innovation

The UVLACK industry continues to evolve, with new formulations and application techniques enhancing its performance. Innovations such as hybrid coatings that combine UV curing with other chemical processes are expanding the range of achievable finishes. Advances in UV lamp technology, such as the adoption of energy-efficient LED UV systems, further increase efficiency while lowering operational costs. Research into flexible UVLACK applications also opens doors for its use on unconventional surfaces, expanding its market potential even further.

UVLACK in Construction and Architecture

Construction and architecture increasingly integrate UVLACK coatings for surfaces that demand durability and visual appeal. From flooring solutions in commercial spaces to decorative panels in modern interiors, UVLACK provides protection against heavy usage and environmental stress. Architects value UVLACK for its ability to maintain color vibrancy and gloss even in areas exposed to sunlight, while builders appreciate its strength in high-traffic zones. This fusion of aesthetics and resilience makes UVLACK a modern solution in design and construction projects worldwide.

Future Prospects of UVLACK

The future of UVLACK appears promising, with rising global demand for efficient, durable, and sustainable finishes. As industries increasingly prioritize eco-friendly solutions, UVLACK’s minimal VOC emissions and energy-efficient curing process align with global environmental goals. The growing use of UVLACK in industries such as healthcare, aerospace, and packaging suggests that its applications will only continue to expand. Ongoing research into nanotechnology-enhanced coatings further enhances the potential for UVLACK, creating finishes that can self-heal or resist even harsher conditions.

Conclusion

UVLACK has established itself as a transformative solution across multiple industries, offering durability, efficiency, and environmental advantages. From furniture and automotive to electronics and architecture, UVLACK continues to redefine how surfaces are protected and enhanced. Its unique ability to deliver long-lasting, aesthetically appealing finishes while remaining eco-conscious positions it as a key player in modern manufacturing and design. As innovation continues to push UVLACK into new territories, its importance will only grow, cementing its role as a cornerstone of advanced surface technology.