Kalibraatio is a term rooted in precision, accuracy, and reliability. It refers to the process of adjusting and verifying measurement instruments to ensure they provide results that align with established standards. In industries ranging from healthcare and engineering to research and manufacturing, kalibraatio plays a vital role in minimizing errors and guaranteeing consistent outcomes. Whether applied to laboratory equipment, industrial machinery, or consumer devices, the importance of kalibraatio lies in its ability to build trust in data and performance. In this article, we will explore the concept of kalibraatio in detail, outlining its definition, significance, applications, and future potential while keeping the discussion easy to follow yet professionally insightful.

What is Kalibraatio?

Kalibraatio can be defined as the systematic procedure of comparing the readings of an instrument or device against a known reference standard. The goal is to identify any deviations and adjust the instrument so its output matches the standard as closely as possible. This ensures that measurements remain consistent and reliable over time, regardless of external factors. Without kalibraatio, even small inaccuracies in measurement tools could lead to significant errors in critical processes, making it an indispensable practice across industries.

The Importance of Kalibraatio in Modern Industries

The relevance of kalibraatio in today’s industries cannot be overstated. In sectors such as aviation, pharmaceuticals, and electronics, accuracy is directly tied to safety, efficiency, and product quality. A well-calibrated instrument ensures that machines perform optimally, reduces downtime, and avoids costly mistakes. Kalibraatio also supports compliance with international standards and regulatory bodies, which often mandate regular calibration schedules. By prioritizing kalibraatio, businesses not only maintain operational integrity but also enhance their reputation for reliability and quality assurance.

Principles Behind Kalibraatio

At its core, kalibraatio is based on the principles of comparison and correction. Every calibration process begins with a reference standard—usually a highly precise device certified by an accredited authority. The instrument under calibration is tested against this standard to identify discrepancies. If deviations exist, adjustments are made either manually or digitally to bring the device in line with the standard. This principle ensures that every measurement taken after kalibraatio reflects accuracy, consistency, and traceability, which are fundamental in scientific and industrial practices.

Different Types of Kalibraatio

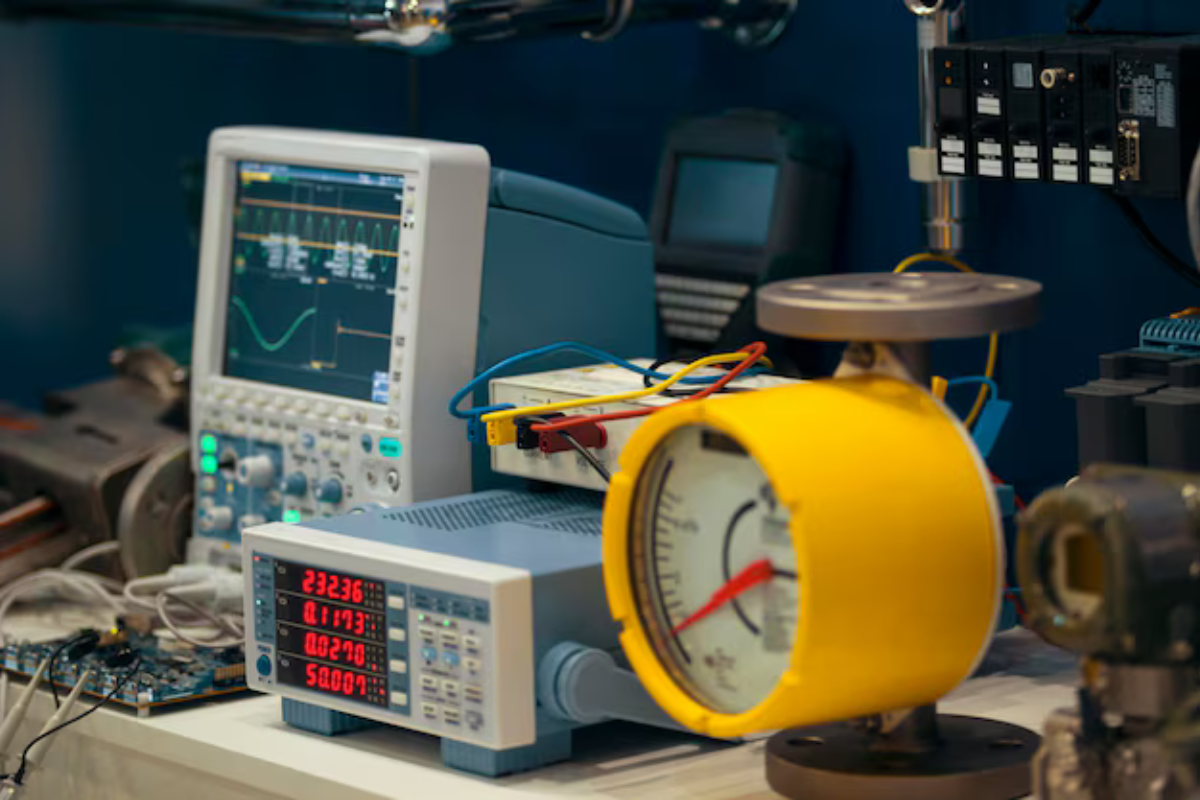

Kalibraatio is not a one-size-fits-all process; it varies depending on the instrument and its application. Electrical calibration involves verifying multimeters, oscilloscopes, or sensors for accurate readings. Mechanical calibration applies to tools such as torque wrenches and pressure gauges. Thermal calibration checks temperature-sensitive devices like thermometers and thermal cameras, while dimensional calibration covers instruments like calipers and micrometers. Each type of kalibraatio follows specific procedures and standards, ensuring that instruments perform with the precision required for their intended use.

Kalibraatio in Scientific Research

In research laboratories, kalibraatio ensures that experimental results are credible and reproducible. Scientific experiments often rely on precise measurements of mass, temperature, volume, or chemical concentration. Even slight deviations can compromise an entire study. Through kalibraatio, researchers establish a foundation of accuracy, making their data dependable and publishable. This is especially crucial in fields such as medical research and environmental studies, where accurate readings influence policy decisions and treatment protocols.

Kalibraatio and Quality Control

Quality control is inseparable from kalibraatio. Manufacturing industries depend on calibrated instruments to meet product specifications and maintain uniformity. For example, in automotive production, calibrated torque wrenches ensure that bolts are tightened to exact specifications, preventing mechanical failure. In the food industry, calibrated thermometers guarantee safe cooking and storage temperatures. Kalibraatio acts as a safeguard, ensuring that quality benchmarks are consistently met and products remain safe for end users.

How Often Should Kalibraatio Be Performed?

The frequency of kalibraatio depends on the instrument’s usage, criticality, and manufacturer’s guidelines. High-use instruments in safety-critical fields may require calibration daily or weekly, while less frequently used devices may only need annual checks. Environmental conditions such as temperature fluctuations, vibrations, or exposure to chemicals can also affect calibration needs. Regular kalibraatio schedules, supported by record-keeping, ensure that instruments do not drift from their standards and continue to perform accurately.

Kalibraatio and Compliance Standards

Regulatory bodies worldwide recognize the importance of calibration and often require documented proof of it. For instance, ISO 9001 emphasizes measurement accuracy as part of quality management systems. Similarly, laboratories accredited under ISO/IEC 17025 must demonstrate regular calibration of their equipment. Kalibraatio not only ensures compliance with such standards but also builds trust with clients, stakeholders, and regulatory authorities, as it demonstrates commitment to precision and accountability.

Digital Transformation and Kalibraatio

The rise of digital technologies has revolutionized kalibraatio. Modern calibration systems are increasingly automated, using advanced software to reduce human error and improve efficiency. Digital calibration records enhance traceability, making it easier to audit and maintain compliance. With the integration of IoT and AI, predictive maintenance is becoming possible, allowing instruments to signal when calibration is required before errors occur. This digital evolution ensures that kalibraatio remains relevant in a fast-changing industrial landscape.

Challenges in Kalibraatio

Despite its importance, kalibraatio faces certain challenges. One major issue is cost, as calibration services can be expensive, particularly for highly specialized equipment. Time is another factor; taking instruments out of service for calibration can disrupt workflows. There is also a shortage of skilled calibration professionals in some regions, which can delay the process. However, organizations that prioritize kalibraatio understand that the long-term benefits of accuracy, compliance, and safety far outweigh these temporary inconveniences.

Kalibraatio in Healthcare and Medicine

In healthcare, kalibraatio directly affects patient safety. Medical devices such as blood pressure monitors, infusion pumps, and ventilators must be calibrated regularly to ensure correct readings. An uncalibrated device could lead to misdiagnosis or improper treatment. Hospitals and clinics establish strict calibration protocols to align with healthcare regulations and provide the highest standard of care. By ensuring accuracy, kalibraatio not only protects patients but also enhances the credibility of healthcare institutions.

Future of Kalibraatio

The future of kalibraatio lies in greater automation, integration with smart technologies, and sustainability. Emerging fields like nanotechnology and renewable energy will demand unprecedented levels of accuracy, making advanced calibration methods essential. Portable calibration devices are likely to become more common, allowing on-site calibration without disrupting workflows. As industries shift toward greener practices, eco-friendly calibration processes and equipment are also expected to gain prominence. Kalibraatio will continue to evolve, staying at the forefront of technological innovation.

Kalibraatio in Everyday Life

While kalibraatio is often discussed in industrial or scientific contexts, it also plays a role in daily life. Household thermometers, kitchen scales, and even vehicle speedometers depend on calibration for accuracy. Without it, daily tasks like cooking, exercising, or driving could be compromised. The presence of kalibraatio in everyday items highlights its universal importance, demonstrating that accuracy and reliability extend beyond industries into the personal lives of individuals.

Conclusion

Kalibraatio stands as the cornerstone of accuracy, reliability, and safety across countless sectors. From laboratories and hospitals to factories and homes, its influence is evident in the way we measure, produce, and ensure quality. By aligning instruments with established standards, kalibraatio not only guarantees precision but also fosters trust, compliance, and innovation. As industries continue to evolve, the role of kalibraatio will only grow more significant, shaping a future built on accuracy and dependability.